DTF transfers are the closest thing you can get to screen print look and feel when it comes to customizing apparel.

Creating high-quality transfers that mimic the look and feel of screen printing involves careful attention during both the design and pressing processes. Here are some essential tips to ensure you get that perfect screen print look every time.

Design Tips for Quality Transfers

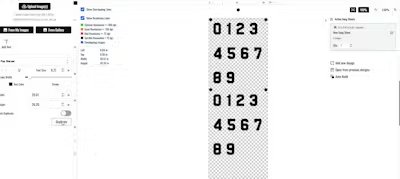

Hollow Letters: Design with hollow letters to let the shirt’s color show through. This makes the transfer feel more integrated with the fabric rather than sitting on top of it.

Background Considerations: Initially, the design might have a background. Removing unnecessary background elements can improve the final product's feel.

Remove Matching Colors: For shirts where the ink color matches the fabric color (e.g., black on black), remove the ink color to allow the shirt color to come through, making the transfer lighter and more breathable.

Heat Press Instructions for Perfect Transfers

Temperature and Time: Press at around 315°F for 15 seconds.

Pressure is Key: Ensure adequate pressure to fully bond the transfer to the shirt. Insufficient pressure can lead to premature wrinkling during washing.

Use Protective Sheets: Consider using a protective guard sheet or parchment paper to provide extra protection for the garment.

Double Press for Best Results: After the initial press, a second press helps achieve a matte finish and locks the transfer deeper into the fabric, enhancing durability and comfort.

By following these design and pressing tips, you can consistently achieve screen print quality with your transfers. Whether you're pressing onto different colored shirts or aiming for that perfect matte finish, these strategies will ensure your transfers look and feel professional every single time.