Looking to maximize efficiency and quality in your DTF transfer process? The way you position garments on your heat press can make a significant difference. Whether you're starting a custom apparel business or planning a large shirt run, understanding when to load (also known as threading or sleeving) versus lay your garments is key to streamlining your workflow and ensuring consistent, professional results.

This article explains loading and laying, compares their benefits, and provides expert tips directly from our production team for achieving professional results with DTF transfers. We'll cover which method works best in most situations, when to make exceptions, and how to optimize your workflow for top-notch prints.

Table Of Contents

What Is Loading?

Loading, also known as threading or sleeving, is a method of positioning your garment on the heat press so that only a single layer of fabric rests on the surface and the rest of the garment wraps underneath the platen. With this technique, only the top layer of material receives direct heat and pressure when applying the DTF transfer, and it is particularly useful for certain types of garments or specific printing situations.

To load a garment, slide it onto the lower platen, typically from the bottom first, so that the collar (or top) is facing you. This keeps the front and back separate while the rest of the garment hangs freely below the platen.

Loading garments is required for other print methods, such as screen printing and DTG, but it's not necessarily needed for DTF printing. Although it can be more time-consuming than laying over the course of larger runs, it's often used for specific garment types or printing locations where isolating a single layer is beneficial.

What Is Laying?

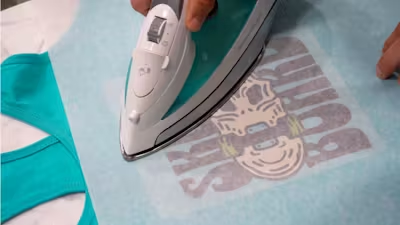

Laying is a simpler method of positioning your garment on the heat press. With this technique, you place the entire garment flat on the lower platen, with both layers of fabric resting on the surface. This method is generally faster than loading, as it requires less manipulation of the garment. Both layers of the garment will be exposed to heat and pressure, but the DTF transfer is only applied to the top layer.

Laying is often preferred for its simplicity and speed, making it ideal for high-volume production. It also allows for easier alignment of the transfer, as the entire garment is visible and accessible on the platen. Refer to our DTF Transfer Placement Guide for detailed information on standard print placements.

What’s Best For DTF Transfers?

In most cases, laying is the preferred method for applying DTF transfers. Here's why:

- Speed: Laying is significantly faster than loading, which can greatly boost your production efficiency—especially for large orders and tight deadlines.

- Accuracy: Laying makes alignment easier because the entire garment is visible. Loading can cause shirts to go slightly crooked or stretched, which can lead to misalignment.

- Consistency: A simpler, repeatable process means fewer variables and more consistent placement across runs.

- Ease of use: Laying is beginner-friendly and requires less manipulation, reducing the chance of errors.

While loading has its place in certain situations (covered next), laying is generally the go-to method for most DTF transfer applications because it balances speed, accuracy, and ease of use.

Exceptions: When To Load

While laying is generally preferred, certain situations call for loading (threading or sleeving) your garments:

- Printing on jerseys: Mesh fabrics (like sports jerseys) need special attention. Loading helps prevent the transfer from sticking to your heat press platen through the fabric’s holes. For more details, check out how to print jerseys with DTF transfers.

- Garments with obstructions: Buttons, zippers, pockets, and heavy seams can interfere with even heat distribution. Loading helps isolate the print area on garments like polos, quarter zips, and pocket hoodies.

- Previously printed garments: If you’re pressing a new design onto a garment that already has a DTF print on the opposite side, loading is safer. A second press usually won’t cause issues, but it reduces the chance of adhesive reactivating and shifting an existing design.

In these cases, loading helps isolate the print area and avoid complications. If you prefer laying, heat press pillows can sometimes act as an alternative by letting you work around obstructions while still laying the garment flat.

Pro Tips For DTF Transfer Success

Whether you're loading or laying, these tips will help you achieve professional results:

- When loading (threading or sleeving), secure your transfer with Thermal Heat Tape so it stays in place as you manipulate the garment.

- Use a Silicone Garment Protector to cover the upper platen. It provides more padding than a standard guard sheet and is especially helpful when laying garments with slight obstructions. Use small magnets to hold it in place.

- Heat Press Pillows can help you avoid loading when printing near zippers, pockets, or buttons. Insert the pillow between layers to create an even surface, and adjust pressure slightly.

- Ensure consistent placement with an Alignment Ruler Set for repeatable, professional results.

- Always do a test print when working with new garment types or designs. Learn more at DTF application and pressing in Ninja University.

Pressing Ahead: Optimizing Your DTF Transfer Workflow

Mastering the art of applying DTF transfers is key to producing high-quality custom apparel. While laying is generally the faster and more efficient method, loading (also known as threading or sleeving) has its place in specific situations. By understanding when to use each technique, you'll be well-equipped to handle a variety of garments and design challenges.

Remember, the goal is to achieve consistent, professional results while maximizing productivity. Experiment with both methods to find what works best for your needs and workflow. Invest in quality supplies like heat press pillows, protective guard sheets, and thermal heat tape to elevate your process.

At Ninja Transfers, we're committed to your success. We offer top-notch DTF transfers and all the supplies you need to apply them flawlessly. Plus, you can source premium blank apparel through Ninja Blanks.